ลองนึกภาพว่าอยู่ในโรงงานที่คึกคักซึ่งเครื่องจักรจำเป็นต้องปรับตัวได้ทันที

มอเตอร์เหนี่ยวนำเหมาะสำหรับโรงงานที่มีโหลดผันแปรเนื่องจากมีประสิทธิภาพที่แข็งแกร่งมีประสิทธิภาพประหยัดต้องใช้การบำรุงรักษาน้อยที่สุดVFD) สำหรับการควบคุมความเร็วที่ปรับได้

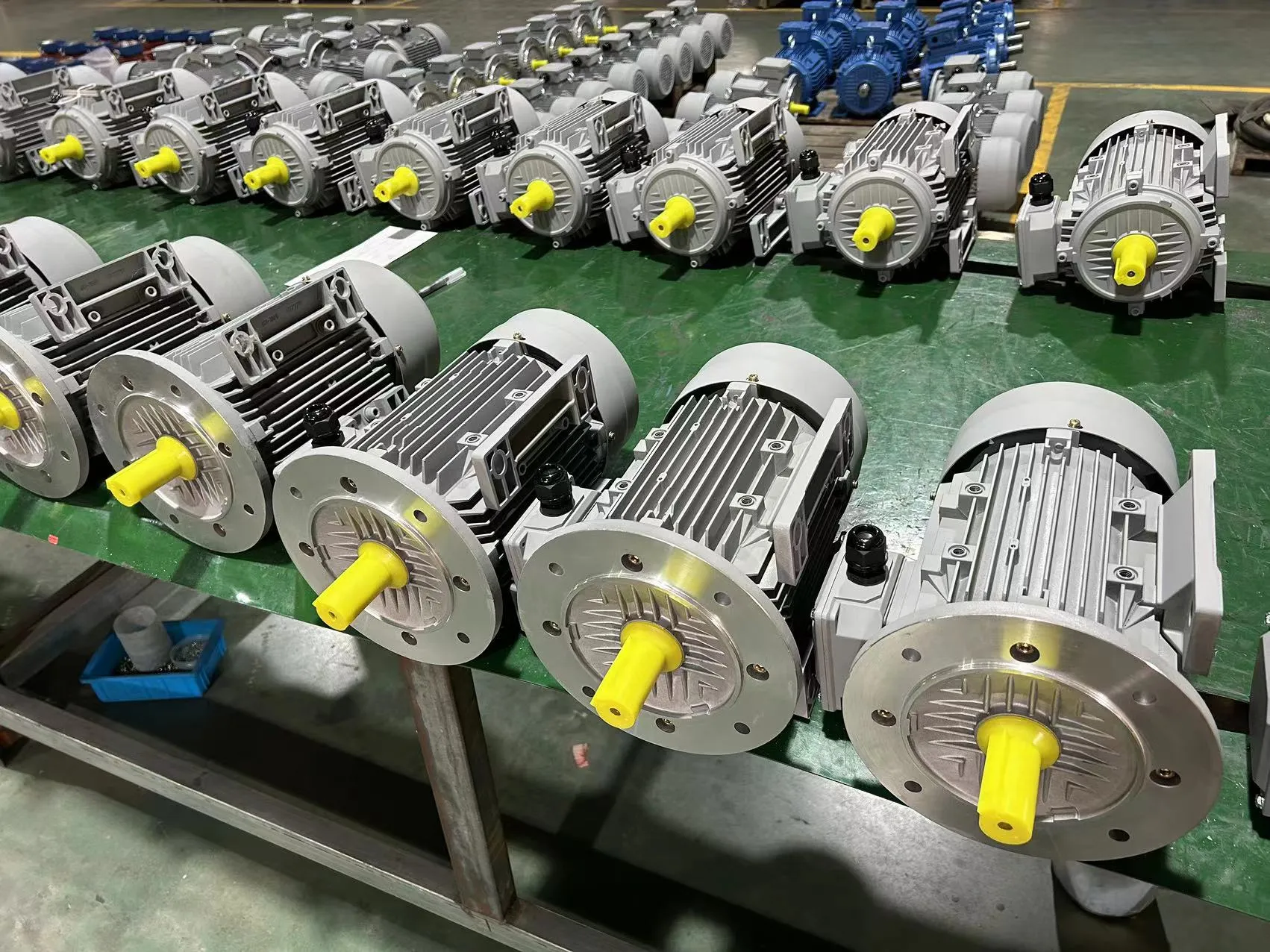

ฉันจำได้ว่าเดินผ่านพื้นโรงงานหนึ่งครั้งดูเครื่องจักรที่ส่งเสียงครวญครางและฮัมปรับให้เข้ากับความต้องการทุกครั้งที่พวกเขาโยน มันเหมือนกับการเป็นพยานการเต้นที่ออกแบบท่าเต้นอย่างสมบูรณ์และมอเตอร์เหนี่ยวนำเป็นดาวของการแสดง มอเตอร์เหล่านี้จัดการกับการเปลี่ยนแปลงโหลดเหมือนแชมป์โดยไม่พลาดจังหวะทำให้พวกเขาขาดไม่ได้ในสภาพแวดล้อมแบบไดนามิกดังกล่าว

ความเรียบง่ายของพวกเขาไม่เพียง แต่ลดต้นทุนลง - มันยังหมายถึงการหยุดทำงานน้อยลงและปวดหัวการบำรุงรักษาน้อยลง และเมื่อจับคู่กับ VFDพวกเขากลายเป็นผู้เชี่ยวชาญด้านประสิทธิภาพปรับความเร็วเพื่อตอบสนองความต้องการที่แน่นอนของช่วงเวลา ความยืดหยุ่นนี้เป็นสาเหตุที่มอเตอร์เหนี่ยวนำมักจะเป็นทางเลือกสำหรับอุตสาหกรรมที่ไม่สามารถชะลอตัวลงได้

มอเตอร์เหนี่ยวนำต้องการการบำรุงรักษาสูงในโรงงานเท็จ

มอเตอร์เหนี่ยวนำเป็นที่รู้จักสำหรับความต้องการการบำรุงรักษาต่ำซึ่งตรงกันข้ามกับการเรียกร้อง

VFDS ช่วยเพิ่มประสิทธิภาพการใช้พลังงานของมอเตอร์เหนี่ยวนำจริง

ตัวแปรความถี่ไดรฟ์ (VFDS) เพิ่มประสิทธิภาพการควบคุมความเร็วเพิ่มประสิทธิภาพ

มอเตอร์เหนี่ยวนำจัดการกับการโหลดได้อย่างมีประสิทธิภาพอย่างไร?

ฉันจำได้ว่าครั้งแรกที่ฉันเห็นมอเตอร์เหนี่ยวนำในการดำเนินการ มันเหมือนกับการดูการเต้นรำของความแม่นยำและอำนาจปรับให้เข้ากับความต้องการที่เปลี่ยนแปลงของสภาพแวดล้อมได้อย่างง่ายดาย

มอเตอร์เหนี่ยวนำจัดการโหลดที่ผันผวนได้อย่างมีประสิทธิภาพโดยใช้การก่อสร้างที่แข็งแกร่งการบำรุงรักษาน้อยที่สุดและการควบคุมความเร็วแบบไดนามิกผ่าน VFDทำให้พวกเขาสมบูรณ์แบบสำหรับอุตสาหกรรมที่มีความต้องการโหลดผันแปร

ประสิทธิภาพที่แข็งแกร่งภายใต้รูปแบบการโหลด

ฉันรู้สึกทึ่งกับวิธีการที่มอเตอร์เหนี่ยวนำรักษาประสิทธิภาพของพวกเขาภายใต้ภาระที่แตกต่างกัน มันเหมือนกับว่าพวกเขามีความยืดหยุ่นภายในนี้เหมือนกับที่ฉันเรียนรู้ที่จะปรับตัวเมื่อชีวิตของชีวิตเร็วขึ้น ของพวกเขา การออกแบบที่เรียบง่าย แต่มีประสิทธิภาพ1 ช่วยให้พวกเขาดูดซับความเครียดโดยไม่ต้องสะดุดเพื่อให้มั่นใจถึงประสิทธิภาพที่สอดคล้องกัน

การดำเนินงานที่คุ้มค่า

เมื่อพูดถึงการจัดการค่าใช้จ่ายมอเตอร์เหนี่ยวนำเตือนให้ฉันนึกถึงรองเท้าที่เป็นมิตรกับงบประมาณและทนทานที่ฉันเคยซื้อมา พวกเขาไม่ได้ทำลายธนาคาร แต่พวกเขาติดตามฉันในการผจญภัยทุกครั้ง ในทำนองเดียวกันการสร้างที่ตรงไปตรงมาของพวกเขาหมายถึงค่าใช้จ่ายล่วงหน้าที่ต่ำกว่าทำให้พวกเขาเป็นตัวเลือกที่เข้าใจได้สำหรับโรงงานที่เล่นกลความต้องการการผลิตผันแปร การลงทุนในตัวพวกเขารู้สึกเหมือนเป็นคนฉลาด เพิ่มประสิทธิภาพงบประมาณ2 โดยไม่ต้องเสียสละคุณภาพ

ความสะดวกในการควบคุมความเร็ว

ครั้งแรกที่ฉันจับคู่มอเตอร์เหนี่ยวนำกับไดรฟ์ความถี่ตัวแปร (VFD) มันเหมือนกับการค้นพบอาวุธลับ ความสามารถในการปรับความเร็วแบบไดนามิกเพื่อให้ตรงกับการโหลดรู้สึกถึงการปฏิวัติ - เช่นการค้นหาเพลย์ลิสต์ที่สมบูรณ์แบบที่ตรงกับทุกอารมณ์ การปรับแบบไดนามิกนี้ให้ทั้งประสิทธิภาพและความยืดหยุ่นโดยเฉพาะอย่างยิ่งสิ่งสำคัญที่ ความแม่นยำเป็นกุญแจสำคัญ3.

ข้อกำหนดการบำรุงรักษาต่ำ

ฉันไม่ใช่แฟนของการดูแลรักษาอย่างต่อเนื่อง - ไม่ว่าจะเป็นรถหรืออุปกรณ์ของฉัน โชคดีที่มอเตอร์เหนี่ยวนำแบ่งปันลักษณะนี้ พวกเขาต้องการการบำรุงรักษาน้อยที่สุด ความทนทานนี้แปลว่าเป็นการหยุดทำงานที่น้อยลงและลดค่าใช้จ่ายซึ่งเป็นเพลงต่อหูของทุกคนที่จัดการตารางงานที่ยุ่งหรือสายการผลิต เป็นความโล่งใจที่รู้ว่าคุณสามารถพึ่งพาพวกเขาเพื่อให้ทำงานได้อย่างราบรื่นและหลีกเลี่ยง การหยุดชะงักที่เกี่ยวข้องกับการบำรุงรักษา4.

ประสิทธิภาพการใช้พลังงาน

มอเตอร์เหนี่ยวนำที่มีประสิทธิภาพสูงเช่นเดียวกับการจัดอันดับ IE3 หรือ IE4 นั้นคล้ายกับการอัพเกรดเป็นหลอดไฟ LED ที่บ้าน-ประหยัดพลังงานในขณะที่ยังคงความสว่าง พวกเขาได้รับการออกแบบมาเพื่อลดการใช้พลังงานซึ่งเป็นสิ่งสำคัญสำหรับการตัดแต่งต้นทุนการดำเนินงานในอุตสาหกรรมที่มีปริมาณงานที่ผันผวน การใช้มอเตอร์เหล่านี้มีส่วนช่วยอย่างมาก การปฏิบัติทางอุตสาหกรรมที่ยั่งยืน5เช่นเดียวกับการเปลี่ยนแปลงเล็กน้อยอาจมีผลกระทบต่อสิ่งแวดล้อมอย่างมาก

| คุณสมบัติ | ผลประโยชน์ |

|---|---|

| ประสิทธิภาพที่แข็งแกร่ง | จัดการการเปลี่ยนแปลงของโหลดได้อย่างมีประสิทธิภาพ |

| คุ้มค่า | การลงทุนเริ่มแรกต่ำกว่า |

| การควบคุมความเร็ว | ปรับปรุงด้วย VFD สำหรับการปรับแบบไดนามิก |

| การบำรุงรักษาต่ำ | ลดค่าใช้จ่ายในการหยุดทำงานและค่าบำรุงรักษา |

| ประสิทธิภาพการใช้พลังงาน | ลดต้นทุนการดำเนินงานที่สูง IE3/IE4 การจัดอันดับ |

มอเตอร์เหนี่ยวนำต้องการการบำรุงรักษาบ่อยครั้งเท็จ

มอเตอร์เหนี่ยวนำได้รับการออกแบบให้มีความต้องการการบำรุงรักษาต่ำ

VFDS ช่วยเพิ่มการควบคุมความเร็วมอเตอร์เหนี่ยวนำจริง

VFDS ปรับความเร็วมอเตอร์แบบไดนามิกปรับปรุงประสิทธิภาพและความยืดหยุ่น

เหตุใดมอเตอร์เหนี่ยวนำจึงเป็นทางเลือกที่คุ้มค่าสำหรับโรงงาน?

ให้ฉันพาคุณเดินทางผ่านโลกที่น่าหลงใหลของมอเตอร์เหนี่ยวนำที่ซึ่งคุ้มค่าตรงตามประสิทธิภาพของอุตสาหกรรม

มอเตอร์เหนี่ยวนำเหมาะสำหรับการใช้งานจากโรงงานเพราะมีประสิทธิภาพที่แข็งแกร่งต้องการการบำรุงรักษาเพียงเล็กน้อยและประหยัดพลังงาน การออกแบบที่ตรงไปตรงมาของพวกเขาทำให้ต้นทุนเริ่มต้นต่ำทำให้พวกเขาเป็นตัวเลือกที่ชาญฉลาดสำหรับการจัดการโหลดที่แตกต่างกันในการตั้งค่าอุตสาหกรรม

ประสิทธิภาพที่แข็งแกร่งภายใต้รูปแบบการโหลด

ฉันจำได้ว่าครั้งแรกที่ฉันเห็นมอเตอร์เหนี่ยวนำในการดำเนินการ มันเหมือนกับการดูการเต้นรำที่สง่างามที่เครื่องจักรปรับตัวเข้ากับจังหวะของพื้นโรงงานได้อย่างง่ายดาย มอเตอร์เหล่านี้ถูกสร้างขึ้นเพื่อรองรับการโหลดที่ผันผวนโดยไม่ต้องข้ามจังหวะซึ่งเป็นสิ่งจำเป็นเมื่อความต้องการการผลิตเปลี่ยนจากตอนเช้าเป็นกลางคืน มันเหมือนกับการมีพันธมิตรที่เชื่อถือได้ซึ่งปรับให้เข้ากับสิ่งที่มา

ตัวอย่างเช่นพิจารณาสถานการณ์ที่โรงงานประสบกับความต้องการการผลิตที่แตกต่างกันตลอดทั้งวัน มอเตอร์เหนี่ยวนำปรับให้เข้ากับการเปลี่ยนแปลงเหล่านี้ได้อย่างราบรื่นทำให้มั่นใจได้ว่าการดำเนินการที่ราบรื่นโดยไม่จำเป็นต้องปรับเปลี่ยนด้วยตนเองอย่างต่อเนื่อง

การดำเนินงานที่คุ้มค่า

ฉันเป็นคนที่เฝ้าดูงบประมาณของฉันอย่างใกล้ชิดโดยเฉพาะอย่างยิ่งเมื่อทำการซื้อสินค้าครั้งใหญ่ ความงามของมอเตอร์เหนี่ยวนำอยู่ในความเรียบง่ายของพวกเขา - พวกเขามาพร้อมกับป้ายราคาที่ต่ำกว่าเมื่อเทียบกับประเภทอื่น ๆ แต่พวกเขาไม่ได้ประนีประนอมกับคุณภาพหรือความน่าเชื่อถือ คิดว่ามันเหมือนกับการซื้อยานพาหนะที่ทนทานและไม่มีการฉีกขาดที่เดินไปเรื่อย ๆ

การตั้งค่าโรงงานทั่วไปมักจะต้องใช้มอเตอร์หลายตัว การเลือกใช้มอเตอร์เหนี่ยวนำช่วยลดการลงทุนเริ่มต้นในขณะที่มั่นใจว่าประสิทธิภาพที่สอดคล้องกัน ด้านนี้เป็นประโยชน์อย่างยิ่งใน ประเทศกำลังพัฒนา6 ในกรณีที่ข้อ จำกัด ด้านงบประมาณเป็นเรื่องปกติ

| ประเภทมอเตอร์ | ต้นทุนเริ่มต้น | ค่าบำรุงรักษา |

|---|---|---|

| มอเตอร์เหนี่ยวนำ | ต่ำ | ต่ำ |

| มอเตอร์ซิงโครนัส | สูง | ปานกลาง |

| มอเตอร์กระแสตรง | ปานกลาง | สูง |

ความสะดวกในการควบคุมความเร็วด้วย VFD

การรวมไดรฟ์ความถี่ตัวแปร (VFD) ด้วยมอเตอร์เหนี่ยวนำให้ความรู้สึกเหมือนการเปิดเผย ลองนึกภาพความสามารถในการปรับความเร็วอุปกรณ์ของคุณเช่นการปรับระดับเสียงในเพลย์ลิสต์ที่คุณชื่นชอบ คุณสมบัตินี้ไม่เพียง แต่ช่วยเพิ่มประสิทธิภาพการใช้พลังงาน แต่ยังทำให้การจัดการค่าใช้จ่ายเป็นเรื่องง่าย

ตัวอย่างเช่นการติดตั้งไฟล์ VFD ระบบ7 เปลี่ยนหน่วยสิ่งทอของเราลดค่าพลังงานอย่างมีนัยสำคัญ

ข้อกำหนดการบำรุงรักษาต่ำ

ไม่มีอะไรน่าหงุดหงิดไปกว่าการหยุดทำงานที่ไม่คาดคิดโดยเฉพาะอย่างยิ่งในช่วงระยะเวลาการผลิตสูงสุด มอเตอร์เหนี่ยวนำเป็นของฉันไปเพราะพวกเขาไม่ค่อยต้องการความสนใจซึ่งแปลว่าหยุดทำงานน้อยลงและเพิ่มผลิตภาพมากขึ้น

โรงงานที่ทำงานในตารางเวลาที่เข้มงวดได้รับประโยชน์อย่างมากจากด้านนี้เนื่องจากการบำรุงรักษาน้อยลงหมายถึงการหยุดชะงักน้อยลงและเพิ่มผลิตภาพมากขึ้น

มาตรฐานประสิทธิภาพการใช้พลังงาน

เปลี่ยนเป็นมอเตอร์เหนี่ยวนำประสิทธิภาพสูง (IE3/IE4) เป็นหนึ่งในการเคลื่อนไหวที่ฉลาดที่สุดสำหรับการดำเนินงานในโรงงานของเรา มอเตอร์เหล่านี้ใช้พลังงานน้อยลงและสอดคล้องกับเป้าหมายการพัฒนาอย่างยั่งยืนของเรา - ช่วยประหยัดเงินและโลกพร้อมกัน!

โดยการบูรณาการ มอเตอร์ประหยัดพลังงาน8เราได้เห็นการประหยัดต้นทุนที่เห็นได้ชัดเจนซึ่งแสดงให้เห็นถึงการลงทุนหลายครั้ง

มอเตอร์เหนี่ยวนำต้องการการบำรุงรักษาบ่อยครั้งในโรงงานเท็จ

มอเตอร์เหนี่ยวนำมีความต้องการการบำรุงรักษาต่ำเนื่องจากการออกแบบที่แข็งแกร่ง

VFDs เพิ่มประสิทธิภาพการใช้พลังงานของการเหนี่ยวนำมอเตอร์ในโรงงานจริง

VFDs อนุญาตให้ควบคุมความเร็วแบบไดนามิกปรับการใช้พลังงานให้เหมาะสม

เหตุใดการควบคุมความเร็วจึงง่ายขึ้นด้วยมอเตอร์เหนี่ยวนำ?

เคยสงสัยหรือไม่ว่าทำไมมอเตอร์เหนี่ยวนำจึงเป็นทางเลือกในการควบคุมความเร็วที่แม่นยำในหลายอุตสาหกรรม? มันเหมือนกับว่าพวกเขามีซอสลับที่ทำให้ทุกอย่างทำงานได้อย่างราบรื่น

มอเตอร์เหนี่ยวนำเหมาะสำหรับการควบคุมความเร็วเพราะมันรวมเข้ากับไดรฟ์ความถี่ตัวแปรได้อย่างราบรื่น (VFD) อนุญาตให้ปรับความเร็วได้อย่างแม่นยำและมีประสิทธิภาพซึ่งประหยัดพลังงานและเพิ่มประสิทธิภาพประสิทธิภาพภายใต้การเปลี่ยนเงื่อนไขการโหลด

บทบาทของไดรฟ์ความถี่ผันแปร

ฉันจำครั้งแรกที่ฉันเห็นไฟล์ ไดรฟ์ความถี่ผันแปร9 -VFD) ในการดำเนินการ มันเหมือนกับการดู Maestro ดำเนินการวงออเคสตราแต่ละองค์ประกอบที่ทำงานอย่างกลมกลืนเพื่อให้สิ่งต่าง ๆ ปรับแต่ง ความงามของการจับคู่ VFD ด้วยมอเตอร์เหนี่ยวนำอยู่ในความสามารถในการปรับความเร็วของมอเตอร์โดยการเปลี่ยนความถี่ของแหล่งจ่ายไฟฟ้า สิ่งนี้มีความสำคัญในสภาพแวดล้อมที่สภาพเปลี่ยนแปลงบ่อยเช่นสายการผลิตที่ต้องเปลี่ยนเกียร์ทันทีโดยไม่พลาดจังหวะ

ประสิทธิภาพการใช้พลังงานและการประหยัดต้นทุน

เมื่อคุณรวมกัน VFD ด้วยมอเตอร์เหนี่ยวนำที่มีประสิทธิภาพสูงมันเหมือนกับการตีแจ็คพอตในแง่ของการประหยัดพลังงาน ฉันจำได้ว่าไปเยี่ยมโรงงานที่พวกเขาใช้มอเตอร์เหล่านี้และเจ้าของไม่สามารถหยุดพูดถึงค่าพลังงานที่ลดลงได้ มันเป็นตัวเปลี่ยนเกมสำหรับพวกเขา พวกเขาจัดการเพื่อลดการใช้พลังงานที่ไม่จำเป็นส่งผลให้ต้นทุนการดำเนินงานลดลงอย่างมีนัยสำคัญ - การพิจารณาที่สำคัญเมื่อต้องรับมือกับความต้องการการผลิตที่ผันผวน

| คุณสมบัติ | ประโยชน์ |

|---|---|

| การควบคุมความเร็วแบบไดนามิก | ประสิทธิภาพที่เหมาะสมที่สุด |

| ประสิทธิภาพการใช้พลังงาน | ลดต้นทุนการดำเนินงาน |

| ความเข้ากันได้กับ VFD | การรวมและการตั้งค่าที่ราบรื่น |

ประสิทธิภาพที่แข็งแกร่งภายใต้รูปแบบการโหลด

มอเตอร์เหนี่ยวนำเป็นเหมือนวีรบุรุษที่ไม่ได้รับการคัดเลือกในอุตสาหกรรมที่มีภาระงานที่คาดเดาไม่ได้ การออกแบบของพวกเขามีความแข็งแกร่งโดยเนื้อแท้จัดการกับความหลากหลายของโหลดด้วยความสง่างามโดยเฉพาะอย่างยิ่งเมื่อถูกชี้นำโดย VFD- ภาพสิ่งนี้: คุณกำลังใช้โรงงานสิ่งทอและทันใดนั้นก็มีความต้องการที่เพิ่มขึ้น แทนที่จะงงงวยมอเตอร์เหล่านี้ปรับได้อย่างราบรื่นทำให้มั่นใจได้ว่าประสิทธิภาพและความน่าเชื่อถือโดยไม่ต้องข้ามจังหวะ

นอกจากนี้ของพวกเขา ความเรียบง่ายของการออกแบบ10 หมายความว่าพวกเขามีการบำรุงรักษาต่ำ-ชิ้นส่วนที่ต้องเสื่อมสภาพหมายถึงการหยุดทำงานน้อยลง ฉันเคยเห็นโดยตรงว่าธุรกิจจะได้รับประโยชน์จากสิ่งนี้ลดการหยุดชะงักและทำให้ผลผลิตสูงที่สุด

แอปพลิเคชันและตัวอย่างที่ใช้งานได้จริง

ในการตั้งค่าในโลกแห่งความเป็นจริงฉันได้เห็นว่าอุตสาหกรรมใช้ประโยชน์จากมอเตอร์เหล่านี้สำหรับงานเช่นสายพานลำเลียงหรือใช้สายการประกอบอัตโนมัติ ด้วยการปรับความเร็วแบบไดนามิกมอเตอร์เหนี่ยวนำให้ทุกอย่างฮัมเพลงอย่างราบรื่นป้องกันคอขวดที่น่ากลัวหรือเวลาว่าง

การทำความเข้าใจกับแง่มุมเหล่านี้ช่วยให้วิศวกรและเจ้าหน้าที่จัดซื้อจัดจ้างดูว่าทำไมการลงทุนในมอเตอร์เหนี่ยวนำจึงเป็นความคิดที่ชาญฉลาดสำหรับการดำเนินงานอุตสาหกรรมที่ทันสมัย

มอเตอร์เหนี่ยวนำต้องปรับความเร็วด้วยตนเองเท็จ

VFDS เปิดใช้งานการปรับความเร็วอัตโนมัติโดยไม่จำเป็นต้องมีการแทรกแซงด้วยตนเอง

VFDs ลดการใช้พลังงานในมอเตอร์เหนี่ยวนำจริง

ด้วยการปรับความเร็วมอเตอร์เพื่อให้ตรงกับความต้องการโหลด VFDS เพิ่มประสิทธิภาพการใช้พลังงาน

มอเตอร์เหนี่ยวนำมีส่วนช่วยในการใช้พลังงานในโรงงานอย่างไร

จำครั้งแรกที่คุณรู้ว่าโรงงานสามารถบริโภคพลังงานได้มากแค่ไหน? มันส่าย! แม้ว่ามอเตอร์เหนี่ยวนำจะเป็นเหมือนฮีโร่ที่ไม่ได้รับการปฏิวัติอย่างเงียบ ๆ อย่างเงียบ ๆ ในการตั้งค่าอุตสาหกรรม

มอเตอร์เหนี่ยวนำเป็นตัวเปลี่ยนเกมในโรงงานโดยการรักษาประสิทธิภาพภายใต้การเปลี่ยนแปลงโหลดลดความต้องการการบำรุงรักษาและการเพิ่มประสิทธิภาพความเร็วด้วยไดรฟ์ความถี่ผันแปร (VFD) ซึ่งลดการใช้พลังงานเข้าด้วยกัน

ประสิทธิภาพที่แข็งแกร่งภายใต้รูปแบบการโหลด

มอเตอร์เหนี่ยวนำเจริญเติบโตในสภาพแวดล้อมโรงงานที่คึกคักเพราะพวกเขาจัดการโหลดที่ผันผวนได้อย่างง่ายดาย ลองนึกภาพพวกเขาในฐานะผู้ทำงานที่เชื่อถือได้ซึ่งดำเนินต่อไปอย่างแข็งแกร่งทำให้มั่นใจได้ว่าพลังงานทุกออนซ์จะถูกใช้อย่างชาญฉลาดแม้ในขณะที่การผลิตต้องการการเปลี่ยนแปลงอย่างกะทันหัน ความสามารถในการปรับตัวนี้มีความสำคัญในอุตสาหกรรมที่ความต้องการการผลิตสามารถเปลี่ยนแปลงได้อย่างรวดเร็ว

การดำเนินงานที่คุ้มค่า

ในช่วงแรก ๆ ที่ฉันทำงานกับมอเตอร์ไฟฟ้าฉันประหลาดใจกับการออกแบบที่ตรงไปตรงมาของพวกเขาส่งผลให้ต้นทุนล่วงหน้าลดลง โรงงานสามารถประหยัดขนาดใหญ่ด้วยมอเตอร์เหล่านี้และการออมไม่ได้หยุดอยู่แค่นั้น การบำรุงรักษาที่น้อยที่สุดหมายถึงความประหลาดใจที่น้อยลงและทรัพยากรมากขึ้นในการลงทุนในเทคโนโลยีประหยัดพลังงานอื่น ๆ ผู้จัดการโรงงานสามารถจัดสรรเงินทุนที่บันทึกไว้ในเทคโนโลยีประหยัดพลังงานอื่น ๆ

ความสะดวกในการควบคุมความเร็วด้วย VFD

เพื่อนร่วมงานเคยแบ่งปันเรื่องราวเกี่ยวกับวิธีที่โรงงานของพวกเขาลดขยะพลังงานอย่างมีนัยสำคัญโดยใช้ไดรฟ์ความถี่ผันแปร (VFD) ด้วยมอเตอร์เหนี่ยวนำของพวกเขา ไดรฟ์เหล่านี้ช่วยให้มอเตอร์สามารถปรับความเร็วแบบไดนามิกได้อย่างสมบูรณ์แบบกับความต้องการของโรงงานโดยไม่ต้องเผาผลาญพลังงานพิเศษ มันเหมือนกับการควบคุมความเร็วคงที่สำหรับเครื่องจักรของคุณ - ประหยัดและราบรื่น

| ประโยชน์ของการใช้งาน VFD | ผลกระทบต่อประสิทธิภาพการใช้พลังงาน |

|---|---|

| ปรับปรุงการควบคุมความเร็ว | การสูญเสียพลังงานลดลง |

| ปรับปรุงกระบวนการควบคุม | การใช้พลังงานที่เหมาะสมที่สุด |

| อายุการใช้งานอุปกรณ์ขยาย | ลดต้นทุนการดำเนินงาน |

ข้อกำหนดการบำรุงรักษาต่ำ

หนึ่งในมอเตอร์เหนี่ยวนำที่ฉันชื่นชมอย่างแท้จริงคือความต้องการการบำรุงรักษาต่ำ ด้วยการหยุดทำงานน้อยลงเนื่องจากการพังทลายน้อยลงโรงงานสามารถให้ความสำคัญกับพวกเขา - และงบประมาณ - เพื่อเพิ่มประสิทธิภาพด้านอื่น ๆ มันเหมือนกับการมีเพื่อนที่เชื่อถือได้ซึ่งมักจะปรากฏตัวขึ้นไม่มีความยุ่งยาก

โมเดลที่มีประสิทธิภาพสูง (IE3/IE4-

เมื่อโมเดลที่มีประสิทธิภาพสูงเช่น IE3 และ IE4 เข้ามาในฉากมันเป็นตัวเปลี่ยนเกม มอเตอร์เหล่านี้ทำงานได้อย่างมีประสิทธิภาพมากกว่ารุ่นเก่าตัดการใช้ไฟฟ้าในขณะที่ยังคงประสิทธิภาพสูงสุด สำหรับผู้ที่กระตือรือร้นในรายละเอียดมาตรฐานอุตสาหกรรมเช่น ข้อมูลจำเพาะของมอเตอร์ IE311 สามารถเสนอข้อมูลมากมาย

การผสมผสานมอเตอร์เหนี่ยวนำเข้ากับการดำเนินงานของโรงงานไม่ได้เกี่ยวกับการติดตามเวลา - มันเกี่ยวกับการขับรถไปสู่อนาคตที่ยั่งยืนและมีประสิทธิภาพ

มอเตอร์เหนี่ยวนำจัดการการเปลี่ยนแปลงของโหลดได้อย่างมีประสิทธิภาพจริง

การออกแบบของพวกเขาช่วยให้การรักษาประสิทธิภาพโดยไม่ต้องเสียพลังงาน

มอเตอร์เหนี่ยวนำมีข้อกำหนดการบำรุงรักษาสูงเท็จ

พวกเขาเป็นที่รู้จักสำหรับความต้องการการบำรุงรักษาต่ำและความทนทาน

บทสรุป

มอเตอร์เหนี่ยวนำเหมาะสำหรับโรงงานที่มีโหลดผันแปรเนื่องจากประสิทธิภาพที่แข็งแกร่งการบำรุงรักษาต่ำความคุ้มค่าและประสิทธิภาพการใช้พลังงานโดยเฉพาะอย่างยิ่งเมื่อจับคู่กับไดรฟ์ความถี่ผันแปร (VFD-

-

สำรวจว่าการออกแบบที่ตรงไปตรงมาช่วยให้มอเตอร์เหนี่ยวนำจัดการโหลดที่ผันผวนได้อย่างมีประสิทธิภาพ ↩

-

ค้นพบว่าการประหยัดต้นทุนสามารถทำได้อย่างไรโดยการเลือกมอเตอร์เหนี่ยวนำสำหรับการใช้งานอุตสาหกรรม ↩

-

เรียนรู้เกี่ยวกับข้อดีของการควบคุมความเร็วมอเตอร์ที่แม่นยำในการตั้งค่าอุตสาหกรรมต่างๆ ↩

-

ทำความเข้าใจว่าข้อกำหนดการบำรุงรักษาที่ลดลงจะเป็นประโยชน์ต่อโรงงานโดยใช้มอเตอร์เหนี่ยวนำได้อย่างไร ↩

-

รับข้อมูลเชิงลึกเกี่ยวกับการจัดอันดับที่มีประสิทธิภาพสูงมีส่วนช่วยในการใช้พลังงานอย่างยั่งยืน ↩

-

สำรวจความสามารถในการจ่ายและความน่าเชื่อถือของมอเตอร์เหนี่ยวนำโดยเน้นว่าทำไมพวกเขาถึงชื่นชอบในตลาดที่ใส่ใจงบประมาณ ↩

-

ให้ข้อมูลเชิงลึกว่า VFDS เพิ่มประสิทธิภาพการใช้พลังงานและปรับปรุงประสิทธิภาพของมอเตอร์อย่างไรทำให้มีคุณค่าในการใช้งานอุตสาหกรรม ↩

-

รายละเอียดข้อดีของมอเตอร์ที่มีประสิทธิภาพสูงมุ่งเน้นไปที่การประหยัดต้นทุนและผลกระทบต่อสิ่งแวดล้อม ↩

-

ลิงค์นี้ให้คำอธิบายโดยละเอียดเกี่ยวกับ VFDs ซึ่งสำคัญสำหรับการทำความเข้าใจบทบาทของพวกเขาในการควบคุมความเร็วมอเตอร์เหนี่ยวนำ ↩

-

สำรวจลิงค์นี้เพื่อทำความเข้าใจว่าการออกแบบมอเตอร์เหนี่ยวนำอย่างง่ายมีส่วนช่วยให้พวกเขามีความน่าเชื่อถือและความสะดวกในการบำรุงรักษา ↩

-

ทำความเข้าใจว่าข้อกำหนดของ IE3 ช่วยลดการใช้พลังงานในขณะที่รักษาประสิทธิภาพของมอเตอร์ได้อย่างไร ↩